Branch Production: Robotic Methods for Whole Tree Structures

Workshop edit – video production by 6ix Films (Toronto, CA)

Focused on workflows for making architectural structures from tree branches through adaptive design and digital fabrication.

WORKSHOP LEADERS

Wyatt Armstrong

Hooke Park, Architectural Association

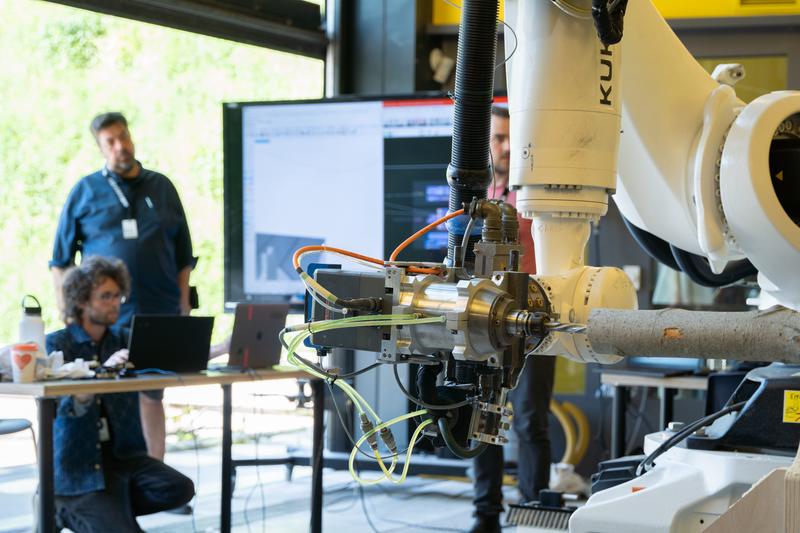

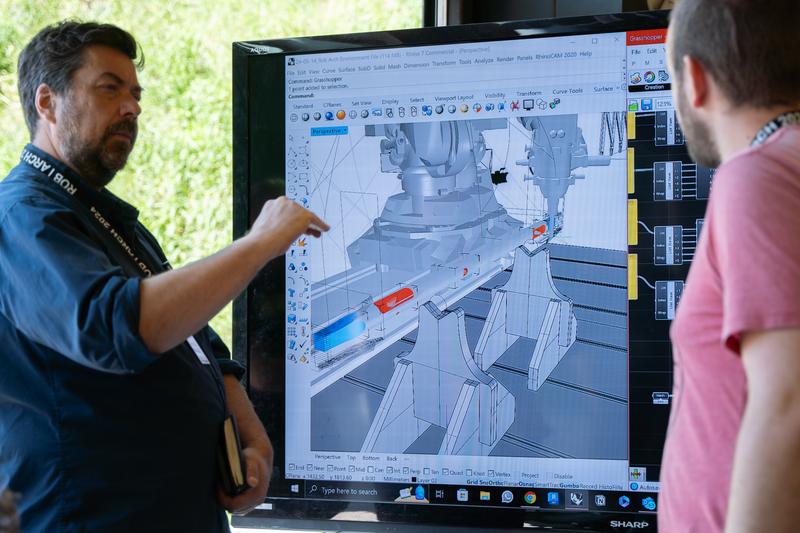

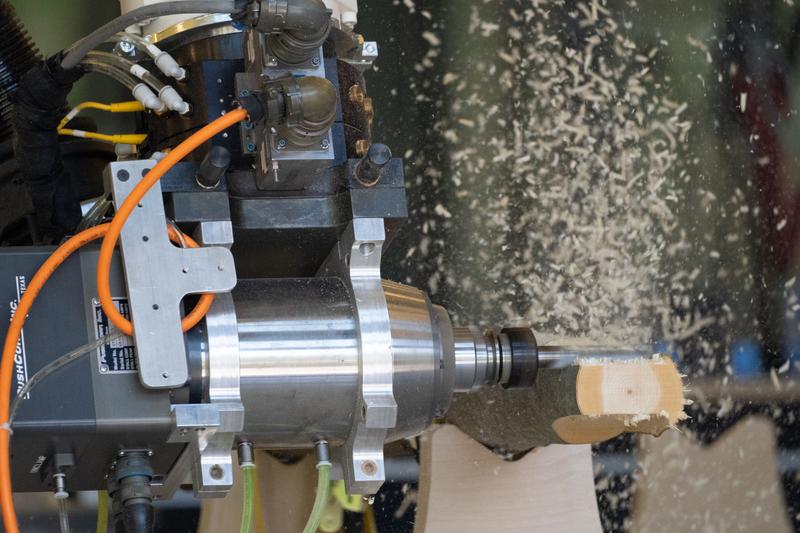

The workshop focused on making architectural structures from irregular tree limbs. Using a robotic workflow that consisted of 3D scanning, digital automation tools, and the high‑bay robotics cell at U of T Daniels, uniquely shaped tree branches were cut to predictable forms at their points of connection to other building elements.

Through the process of preparing the robotics cell for the scanning and fabrication workflows, participants gained hands‑on experience with a variety of software and hardware. They created stock‑holding fixtures, executed tool and workspace calibrations, and set up scanning equipment. Once in operation, parts leaving the cell required hand‑finishing to prepare them for assembly. After all the parts had been produced, participants worked as a team to assemble a structure.

Workshop participants were expected to have prior knowledge of the 3D‑modelling software Rhinoceros and the visual‑scripting software Grasshopper. Before the workshop, they were asked to install the Kuka‑PRC plugin.

Overall, the workshop demonstrated a method of architectural fabrication embedded in a forestry approach that preferred species diversity. Whereas the conventional industrial model relied on a handful of species grown in predictable forms, this workshop pointed toward a new relationship with forests—one that opened the industry to biodiversity and considered using the whole tree in structural applications.