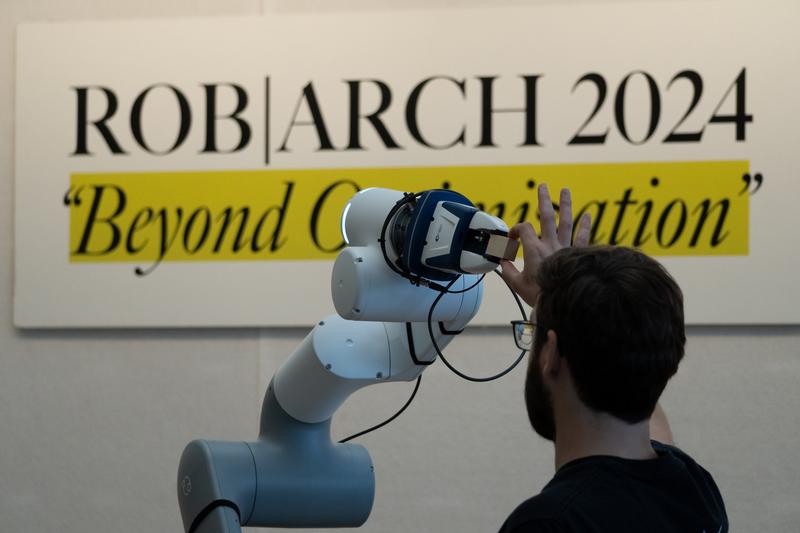

Collaboration between Design and Automated Fabrication: Design for Manufacturing and Assembly Workflows in Architecture with ABB Industrial Robots Using COMPAS_RRC

Workshop edit – video production by 6ix Films (Toronto, CA)

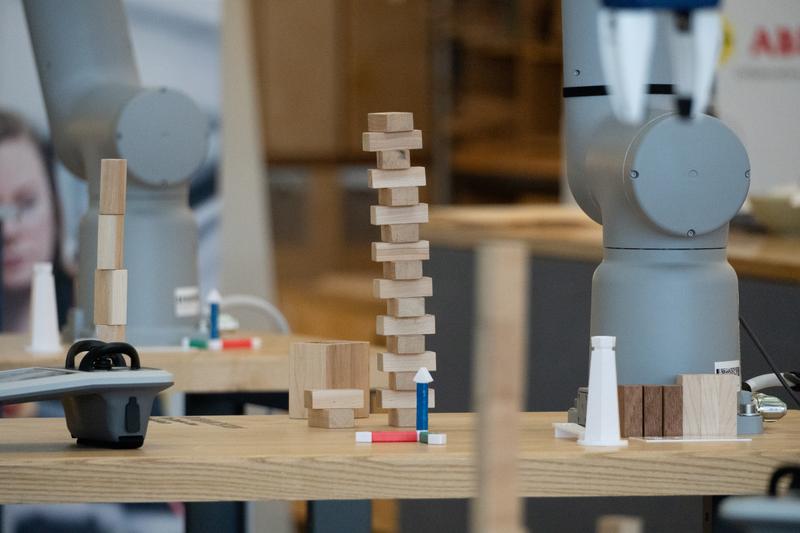

Introduced ABB’s GoFa collaborative robots and the COMPAS_RRC control package for prototyping.

WORKSHOP LEADERS

Sheryl Boyle

CSALT, Azrieli School of Architecture & Urbanism, Carleton University

Philippe Fleischmann

ETH Zürich, Institute of Technology in Architecture (ITA) + Robotic Fabrication Lab (RFL); National Centre of Competence in Research (NCCR) Digital Fabrication

Adonis Lau

CSALT, Azrieli School of Architecture & Urbanism, Carleton University

This hands‑on workshop introduced participants to COMPAS_RRC and ABB’s GoFa collaborative‑robot line. COMPAS_RRC, an easy‑to‑use online control software package for ABB robots—including the GoFa family and RobotWare versions RW5, RW6, and RW7—served as the bridge between design and fabrication. The team led attendees through the complete installation process and demonstrated a design‑for‑manufacturing‑and‑assembly (DfMA) workflow that connected a Rhino/Grasshopper design environment to the robotic‑fabrication setup.

Through small‑scale exercises, participants gained an understanding of basic and advanced COMPAS_RRC functions and investigated how to control multiple robots with a single script. By creating a custom instruction, they engaged the power of the ABB ecosystem, making collaboration with ABB automation specialists more accessible. Lessons learned at test scale could be readily scaled up to future full‑scale productions.

Overall, the workshop equipped participants with skills to harness industrial robotics and pair them with the flexibility of Python‑based frameworks like COMPAS. It invited them to unlock their potential with COMPAS_RRC and embark on further discovery and innovation.